|

H21: Light, Materials and Colour

|

©

James H Nobbs

[Colour4Free]

|

When we are viewing an object or a

surface, it is the light reaching our eyes that conveys the appearance

of the surface to us. The appearance is our interpretation of

the characteristics of the light, characteristics that arise from the

interactions of the light incident on the object with the material of

the object.

The

object may absorb, scatter or reflect the light. Some types

of interaction are wavelength dependent, for example some wavelengths

of light may be absorbed more strongly than other

wavelengths. Other types of interaction may be occurring

giving rise to effects such as interference or luminescence.

|

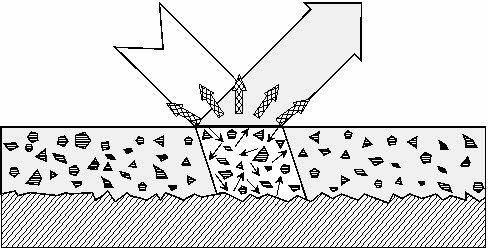

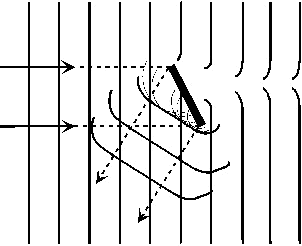

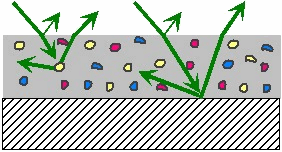

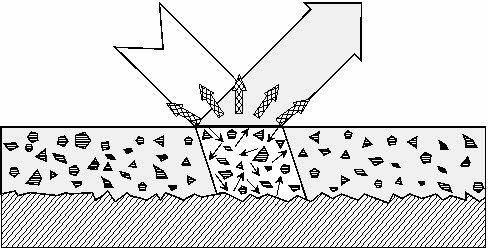

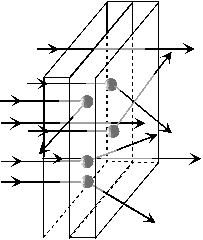

As

an example of the many types of possible interaction, consider the

light shining onto a glossy printed layer, as illustrated in Figure

1. The light will be partially reflected at the surface,

partially absorbed and scattered by the pigments present in the ink

layer, and may be either absorbed or reflected by the underlying

substrate layer.

|

Figure 1: Interactions of a

light beam with printed surface

|

In most

cases, several effects will combine to give the overall colour

appearance of the printed surface. The most common effects

are reflection, refraction, diffraction, absorption, scattering,

interference and luminescence; each of these effects will be discussed

in the following sections.

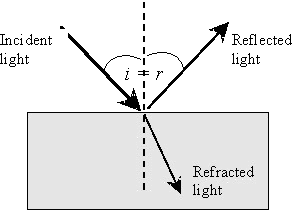

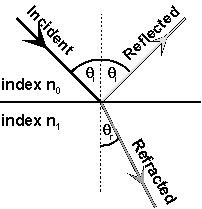

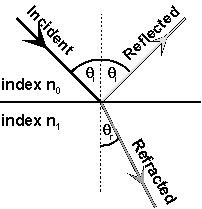

Reflection and refraction

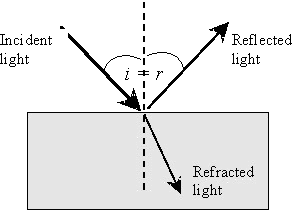

Reflection of light and

refraction of light occur whenever the beam travels across a boundary

between two materials that do not have the same refractive

index. At such a boundary, the incident light is partially

reflected (back from the boundary) and partially refracted (into the

body of the material), due to the change in refractive index.

The process is illustrated in Figure 2.

Boundary reflection

Reflection of light at a

boundary or a surface does not of itself cause colour.

However, in many materials it contributes towards the overall

appearance through the impression of the gloss of the

surface. The boundary reflected light has the spectral

properties of the light source, as it has not entered the material at

all. If the object is illuminated with white light, then the

gloss or boundary reflection is also white light.

The colour of the print is

arises from the light that has passed through the boundary layer and

interacted with the pigments or dyes in the ink layer. When

the print is viewed at an angle so that white gloss light from the

boundary is mixed with the coloured light from the interior,

the intensity of the colour is reduced, making the print

appear lighter and weaker than at other viewing angles.

The proportion of light that

is reflected by the boundary rather than refracted into the layer is

determined by the difference in refractive indices between the two

materials (Fresnel’s law) and by the angle of incidence the light

beam makes with the boundary. For example, a boundary between

air and a high gloss print will reflect more than 4% of the incident

light.

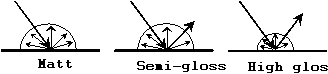

Gloss surface

|

Boundary reflection of

light from a perfectly flat surface follows the well-known law that the

angle of incidence is equal to the angle of reflection (Figure

2). When this mirror like law applies the reflected light is

often known as the specular reflected light.

|

Figure 2 Surface reflection and

refraction

|

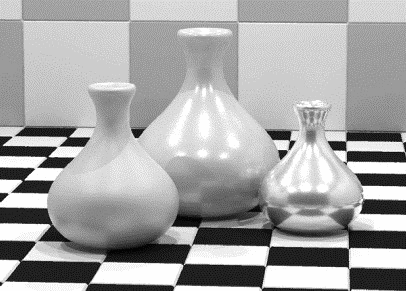

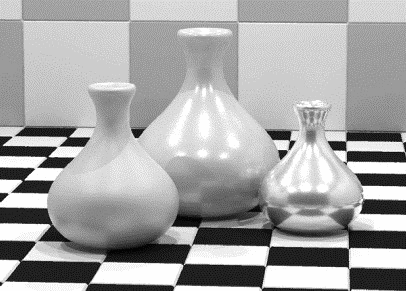

Imagine

that a beam of light is shone at a particular angle onto a very smooth

surface. The boundary reflected light would all be along a

narrow set of directions, the surface would be judged as very

glossy. An observer viewing such a surface will see, at

certain viewing angles, reflected images of the surroundings.

This gives rise to the visual impression of gloss, as illustrated by

the right-hand-side vase of Figure 3.

|

|

Figure

3: Reflection from different types of surface finish

|

|

Matt surface

The boundary of a very rough

surface will tend to reflect light at many different angles, because

the light meets the surface at many different angles. The

boundary reflected light is so diffuse that the observer cannot make

out images of the surroundings. The visual impression is that

of a matt surface, as illustrated by the vase on the left-hand-side of

Figure 3.

This type of appearance

characterisation is best visualised as a polar distribution, as shown

in the lower diagram of Figure 3.

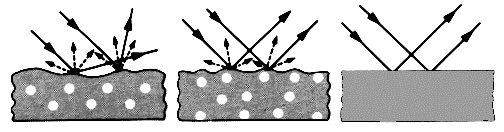

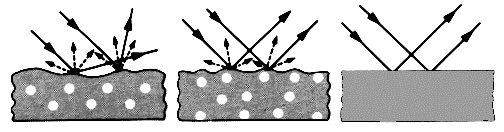

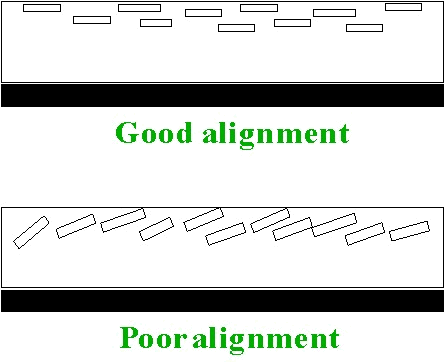

Metallic effect coatings

A

further example of the use of reflection in surface coatings is that of

coatings containing metal flake pigments, such as the metallic effect

paints used on cars. The pigments used in the coatings are

generally aluminium flakes, which act as tiny mirrors within the

coating and increase the amount of white light reflected.

|

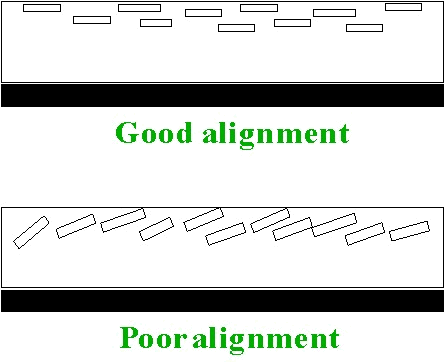

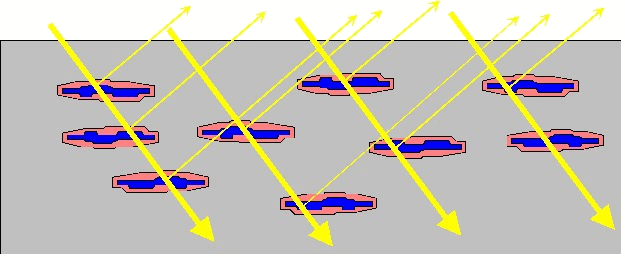

The

surfaces of the flakes are aligned parallel to the surface of the

coating layer, and so enhance reflection at the specular reflection

angle, as illustrated in Figure 4. However, reflection also

occurs from the edges of flakes, and from flakes that are imperfectly

aligned.

|

Figure 4: Flake alignment

|

The

flake reflected light, although highly directional is “spread out” over

a greater angle compared to that from the boundary reflectance of a

highgloss conventional paint. This enhances the look of the

coating, and in particular is thought to enhance the curves on a car

and make it look more sleek and attractive. On closer

inspection, it is also possible to see the individual flakes sparkling

in the light that further increases the attractiveness of the coating.

Refraction

|

When a beam of light is

shone onto a smooth, transparent surface, some of the incident light is

reflected at the boundary and some is transmitted into the

material. The direction of travel of the transmitted beam is

changed from that of the incident beam, the angle made with the normal

to the surface is called the angle of refraction, Figure 5.

|

Figure 5: Reflection and

refraction at a boundary

|

Snell’s

law gives the relationship between the directions of travel.

The splitting of white light

into different colours by a prism and by certain gems arises from

refraction. The refractive index of glass, and many other

materials, changes with the frequency of the light. This

means that blue light is refracted to a different angle compared to red

light as it passes through a glass prism.

The rainbow, colours produced

by water droplets in the atmosphere, is also generated by different

degrees of refraction of the various wavelengths of light as they pass

in and out of the droplets.

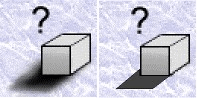

Diffraction

Diffraction

is a form of interaction that all types of waves have with

objects. The effect if the interaction becomes very important

when an object or a pattern has a size or spacing of few times the

wavelength of light.

|

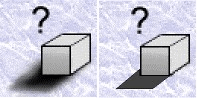

At

its simplest, the effect of diffraction is seen in the shadows cast by

small objects. Figure 6 illustrates the puzzle that the edge of the

shadow is not sharp but fuzzy, and the smaller the object is, the

fuzzier the edge becomes.

|

Figure 6: Diffraction causes the

edges of shadows to be fuzzy instead of sharp

|

|

The

effect is explained by considering how waves flow around and reflect

from by the objects that they meet.

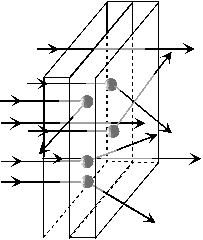

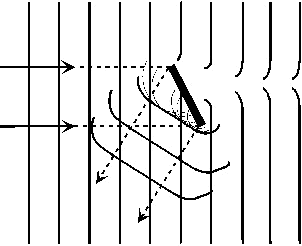

In

Figure 7 a parallel beam of plane waves is shown advancing towards a

small object. The incident beam interacts with each atom in

the surface by inducing oscillations in the position of the electrons,

the oscillation causes the atom to act as an emitter of radiation.

|

Figure 7: Reflection and

diffraction of a wave around a small object

|

The

emitted waves from each neighbouring atom have a definite phase

relationship to each other and combine to produce a short segment of a

“reflected” diffracted wavefront. This wavefront is not

sharply bounded but is spread out; the smaller is the size of the

particle then the more spread out the diffracted edge of the reflected

beam becomes.

Notice also in Figure 7 that

the edges of the transmitted beams are not sharply bounded.

The spreading out of the transmitted beams into the shadow zone causes

the edges of the shadow to be fuzzy.

A second type of diffraction

effect can give rise to colour. If the single object in

Figure 7 is replaced by a series of objects in a regular pattern, then

the “reflected” diffracted beam can be intensely coloured. A

regular spacing can cause the different wavelengths of light to be

reflected into different angles. Many spectrophotometers and

colour measuring instruments make use a device called a diffraction

grating to analyse the incoming beam of light into a series of beams of

different wavelength bands.

Another example of the

creation of a colour effect by a regular spaced pattern is given by the

surface of CD ROM computer disc. The reflected light displays an

intense colour at certain illumination and viewing angles.

Absorption

The selective absorption of

wavelengths from white light is probably the most common cause of the

creation of colour; it occurs in almost all conventional dyes or

pigments, from chlorophyll in plants to indigo in blue jeans.

Examples of the use of light absorption in creating colour might be

dyed fabrics, paint layers, pigmented plastics and printed card.

“Absorption” implies that the

light absorbed is lost as visible light; it may be converted to heat,

or other forms of energy. This conversion may be made in

several ways; the most common involves absorption of light energy by

molecules to excite electrons into a less stable (higher energy)

arrangement within the molecule. The electrons quickly fall

back to their original, stable arrangement, the molecule dissipating

the extra energy as heat.

A system will only absorb

light of particular wavelengths (the absorption band of that system), which correspond exactly

to the amount of energy needed to promote the electrons

involved. The absorption band may be wide, however, due to

the constantly changing vibrational energy of the molecules involved

changing the amount of energy needed for promotion.

Only those substances that

absorb light, radiation in the visible region of the electromagnetic

spectrum, (380 to 730 nm) appear to be coloured.

Transparent materials

A material is called

transparent if it does not contain any particles or discontinuities

that will scatter the light. Examples of coloured transparent

materials are coloured solutions and the inks used in the

four colour printing process.

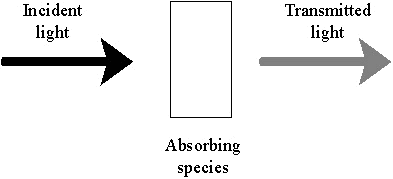

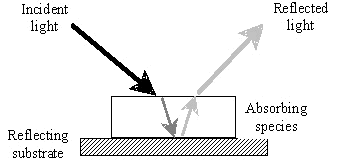

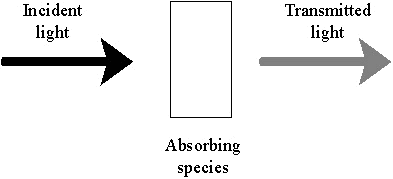

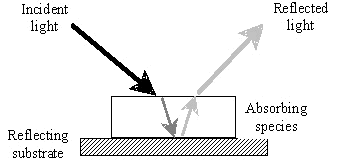

The

simplest case to consider is that of a transparent, coloured material

as illustrated in Figure 8. There are many coloured,

transparent liquids where the light absorbing material is in solution;

lager beer is a good example. In the case of a printed layer,

if no scattering is occurring within the ink, then the light is

refracted on entering the coating layer and selectively absorbed by the

coating material. The remaining light is then reflected by

the substrate as in Figure 9. The emerging light beam has

passed through the coating thickness twice and therefore has twice the

chance to be absorbed.

|

Figure 8: Selective absorption

of light by a transparent, coloured material

|

Figure 9: Passage of light

energy through a transparent coating

|

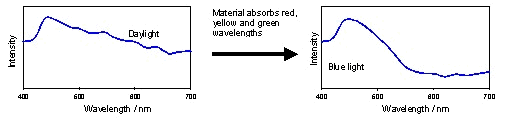

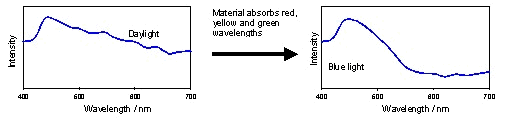

In

Figure 8 and Figure 9, the coloured material is absorbing some of the

light incident on it, and transmitting the remainder. If we

consider the spectral distribution of the intensity of the incident and

transmitted light beams, that is, the light intensity at each

wavelength through the visible spectrum, we might expect to see

something similar to Figure 10.

|

Figure 10: The effect of

selective absorption on the spectral energy distribution

|

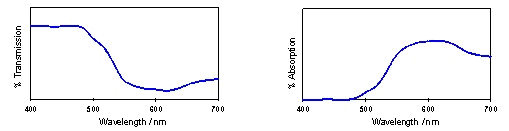

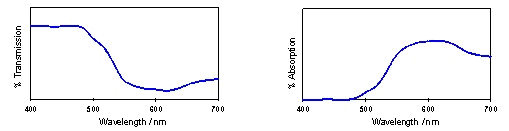

It is

more usual to consider absorption in terms of the relative amounts that

have been transmitted or absorbed, rather than the light

intensities. In other words, we would plot the % ratio of the

intensity of the transmitted (or absorbed) light to intensity of the

incident light, as in Figure 11.

|

Figure 11: Typical plots of

transmission and absorption

|

The

hues of the transmitted colours due to absorption bands centred on

particular wavelengths are given in Table 1. The colour will

also depend on the width and profile of the absorption band.

A wide absorption band may give duller colours as a wider range of

wavelengths is being absorbed. For example, dull olive and

brown shades require absorption almost throughout the visible

spectrum. However, a very thin absorption band may result in

rather pale colours, even if the extinction coefficient is high.

Table 1: Hues of the absorbed light

and the transmitted light

|

Wavelengths

absorbed

|

Hue

of absorbed light

|

Hue

of transmitted light

|

|

400

- 440 nm

|

Violet

|

Greenish

yellow

|

|

400

- 500 nm

|

Blue

|

Yellow

|

|

460

- 500 nm

|

Greenish

blue

|

Orange

|

|

400

- 620 nm

|

Bluish

green

|

Red

|

|

480

- 520 nm

|

Green

|

Magenta

|

|

560

- 700 nm

|

Orange

|

Turquoise

|

|

600

- 700 nm

|

Red

|

Bluish

green

|

If the

profile of the absorption band is very steep and sharp, the colour is

likely to be very pure as light of other wavelengths is transmitted

easily. The absorption “baseline” often gives a good

indication of the purity of the transmitted light.

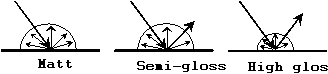

Scattering

of light

|

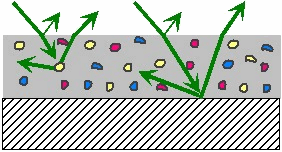

Scattering

describes any process that changes the direction of the light and is

usually associated with the interaction of light with small particles,

as illustrated in Figure 12.

|

Figure 12: Change of direction

by scattering

|

|

In

fact, any change in the refractive index over a small region will cause

scattering. Air bubbles within a liquid or a solid will also

cause scattering and, in the case of beer, is the cause of the white

appearance of the froth at the top of the glass, as shown in Figure 13.

|

Figure 13: Transparent (beer)

and opaque (froth) forms of a liquid

|

The

appearance of a material depends on the extent of scattering of the

light and adjectives such as transparent, translucent, turbid and

opaque are associated with the perceived degree of

scattering. For a colourless material, the degrees of

scattering are approximately:

|

Transparent,

|

none

of the transmitted light has been scattered

|

|

Translucent,

|

of

order of 10% of the transmitted light has been scattered

|

|

Turbid,

|

of

order of 50% of the transmitted light has been scattered

|

|

Opaque,

|

no

light is transmitted through the material

|

The

larger the difference between the refractive indices of the particles

and the surrounding medium then the stronger is the scattering

effect. For this reason, inorganic pigments, which often have

high refractive indices, tend to scatter light much more effectively

than organic pigments. Organic pigments often have refractive

indices of about 1.5, similar to that of the medium in which they are

used. Therefore, printing inks that contain organic pigments

can be almost completely transparent.

Relatively large particles

such as pigments, more than about 2.0 μm

in dimensions, scatter light by the reflection and refraction of the

light. Relatively small particles, less than about 0.3 μm

in dimensions, scatter by diffraction of the light.

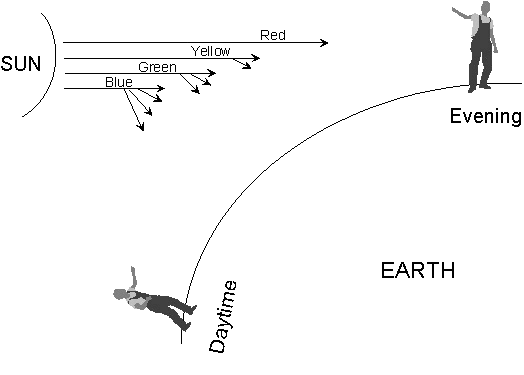

The scattering of light gives

rise to one of the most common colours in the natural world - the blue

of the sky. The sky is not “blue” in the sense that other

wavelengths of light are absorbed. The sky is blue because

blue light is scattered more effectively by very small particles than

light of longer wavelengths.

|

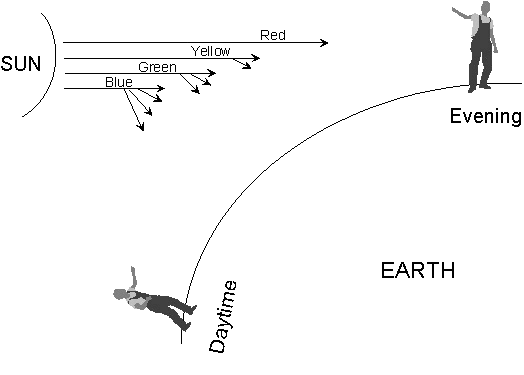

During

the daytime, when the sun is high in the sky, the blue light reaching

our eyes (unless we look directly at the sun, which looks yellowish)

has been scattered by interaction with tiny particles in the

atmosphere. At sunrise and sunset, when the sun is low to the

horizon, we see more of the non-scattered light and the sky appears red

(Figure 14).

|

Figure 14: Blue sky and red

sunset

|

Lord

Rayleigh was the first to explain light scattering by very small

particles. He determined that the intensity of scattering

varies in three ways:

- directly with the intensity of incident light

- directly with the average volume of scattering

particles

- inversely with the fourth power of the

wavelength of incident light.

It is the third relationship

that gives rise to the different scattering power of particles to blue

light compared to red light. Very small particles (less than

about 300 nm in diameter) will scatter blue light (wavelength 400 nm)

over ten times as more strongly than red light (700 nm).

An even more spectacular

illustration of atmospheric scattering is a rainbow, caused by

scattering, (by refraction) of sunlight by very fine water

droplets. Each wavelength of light is scattered to a

different extent and so the familiar spectrum of colours is seen.

Opaque materials

When a material contains a

large amount of pigment, or a coating layer is thick enough, none of

the incident light will penetrate through the material or the coating

layer. The spectrum of the light reflected from an opaque

layer is determined by the absorption and the scattering properties of

the components in the material and does not change very much with the

thickness of the material. Another property of an opaque

material is that the addition of a transparent, colourless diluent to

the material will not change its appearance.

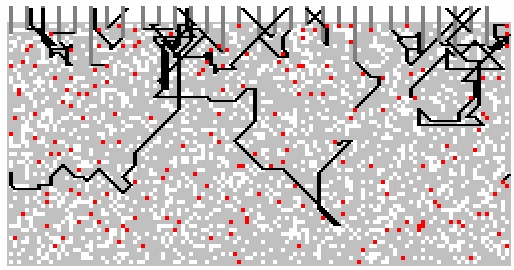

For an

opaque material, the fraction of the incident light reflected at each

wavelength is determined by the ratio of the absorption coefficient to

the scattering coefficient and not on their absolute values.

|

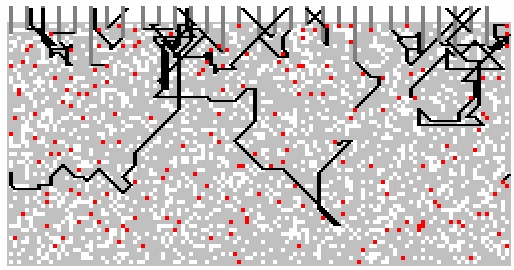

Figure

15 illustrates the paths that photons might take in an opaque,

pigmented material. The figure was obtained by using a

computer program to simulates the interactions of an incident light

beam with a layer composed of a clear medium, a white pigment and a

coloured tinter pigment.

|

Figure 15: Simulated photon

paths, opaque layer

|

Photons

were “fired” at the top surface of the layer and when the photon

encounters a particle, a random number generator is used to decide

whether the photon is absorbed or scattered by the particle.

The figure shows the paths obtained when 30 photons were fired at the

layer.

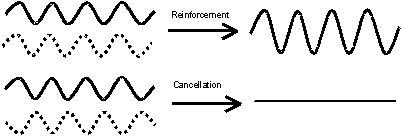

Interference

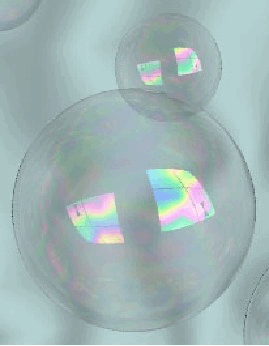

Interference

effects are responsible for the iridescent colours seen in soap

bubbles, in oil droplets and in the wings of many insects.

The basis of this effect is the interaction between beams of light

having the same wavelength and travelling in the same direction.

|

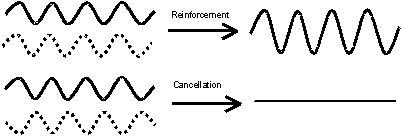

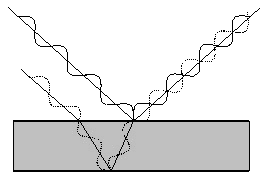

The

oscillating electric fields can interact with each other, causing

either constructive reinforcement or destructive cancellation (Figure

16).

|

Figure 16: Constructive and

destructive interference

|

In order for interference to

occur, the oscillations of the electric fields involved must be exactly

in phase with each other (reinforcement) or 90° out of phase

(cancellation). Ordinary white light is fairly disordered

with respect to phase, the phase of the wave jumps forwards and

backwards every few cycles and this is known as non-coherent

light. Because of this, interference rarely occurs for

ordinary light, except under specific circumstances.

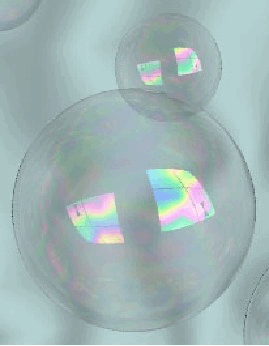

Thin film interference

|

A

common situation when interference can occur is in thin films or layer

structures, as illustrated by the colours shown in the reflections from

the surface of soap bubbles, Figure 17.

The

intensity of the incident light is split at the surface of the film,

and part is reflected from the top boundary and part is refracted into

the material. The refracted beam passes through the layer and

is internally reflected at the lower boundary. The back

reflected beam passes back through the upper surface boundary and then

has the same direction as the top boundary reflected beam.

|

Figure 17: Interference creates

colours in reflections from a soap bubble

|

|

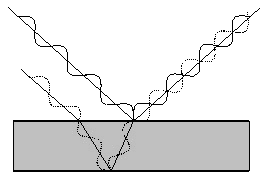

This

is illustrated in Figure 18. Thin-film interference colours

can be seen even with non-coherent incident light so long as the film

is very thin.

In Figure 18 it is

clear that the lower boundary reflected beam has travelled further

through the material than the top boundary reflected beam.

|

Figure 18: Interference due to

reflection at top and lower boundaries of thin film of material

|

Thus, at

a particular angle of viewing the two beams leaving the surface of the

material will be out of phase with each other and interfere

destructively, such that no light emerges. The light energy

is not being lost, merely re-distributed to take part in constructive

interference at another angle of viewing. For a particular

wavelength of light, we can calculate the angles of viewing at which

constructive interference will occur and a bright colour will be seen.

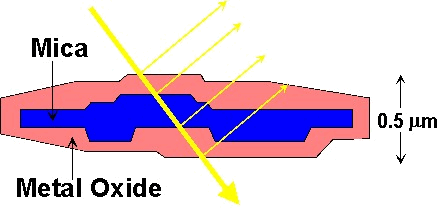

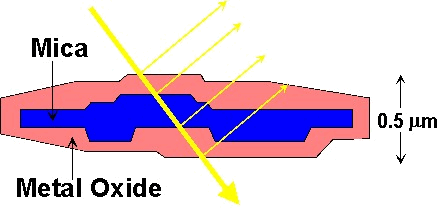

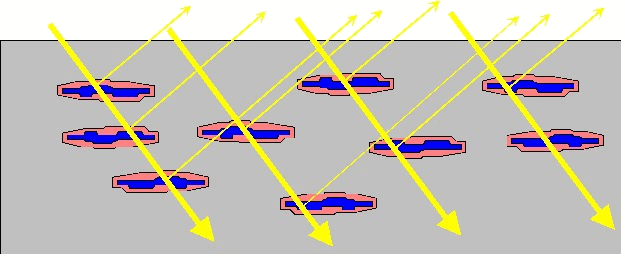

Interference

pigments

Interference pigments make

use of this effect to generate colour from white light. The

pigments are generally composed of platelets of natural mica coated

with a thin layer of a transparent metal oxide (such as titanium

dioxide, chromium (III) oxide or iron (III) oxide), Figure 19.

When

incorporated in a coating, the platelets are aligned such that they

behave as a multiple layer system, Figure 20.

|

Figure 19: Cross section of a

particle of a mica based interference pigment

|

Figure 20: Mica platelets

aligned in a coating layer

|

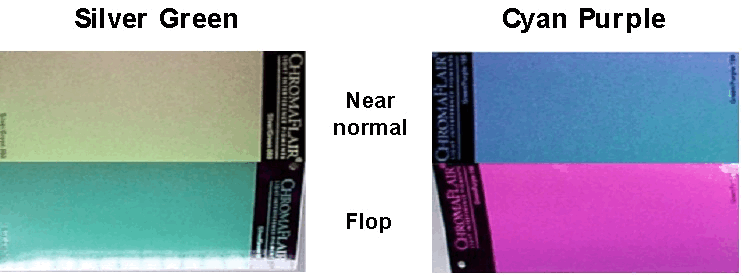

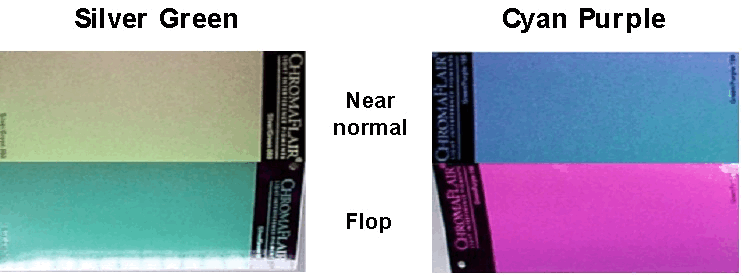

The

thickness of the metal oxide layer is closely controlled such that

interference will occur when the coating is viewed at particular

angles. These coatings thus exhibit what is known as “colour

flop”, whereby the colour seen changes with the angle at which the

surface is illuminated and viewed, as shown in Figure 21.

|

|

Figure 21: Near normal and Flop

colours for coatings containing Chromaflair pigments

|

Luminescence

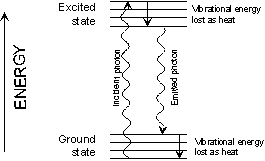

The

term “luminescence” covers the generation of light by the conversion of

other forms of energy. The stimulus energy may be supplied in

many ways such as by heating (thermoluminescence), by the action of an

electrical energy (electroluminescence) or by irradiation with visible

or ultra-violet light (photoluminescence).

|

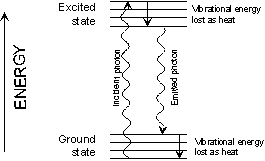

The

most familiar type of luminescence is probably

photoluminescence. Radiation of a relatively short wavelength

(high energy) is absorbed by a material and after a short time; the

energy is emitted as light of a longer wavelength (lower

energy). The energy changes undergone by a molecule are

illustrated in Figure 22. The residual energy is converted to

heat.

|

Figure 22: Loss of energy by

photoluminescence

>

|

For

example, the optical whitening agents used in textiles and in

detergents, absorb ultra-violet radiation and re-emit the energy as

blue light (the “blue-whitener”). Luminous paints act in a

similar way.

Photoluminescence may be

split into fluorescence and phosphorescence. The distinction between these two

is that emission by fluorescence occurs virtually immediately after the

energy is absorbed. The light emission by phosphorescence is

usually delayed and emission by excited molecules may persist for some

time after the removal of the stimulus radiation.

Creation of Colour

It is clear from just looking

around that most coloured objects can be classed as “reflective” or

“surface colours”. They appear coloured because of the

interaction of the white light shining onto their surfaces with the

atoms and molecules within the surface. The majority of

materials produced by the printing industry are surface colours and

understanding the creation of surface colours is the topic of this

section.

The

majority of materials produced by the surface coatings industry and the

printing industry create colour by the action of the dyes or pigments

incorporated into the printing ink or the coating material.

|

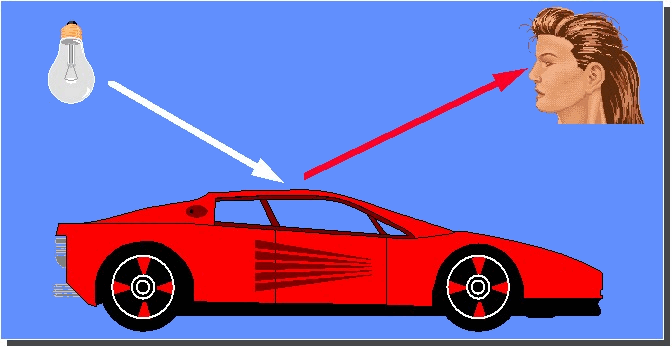

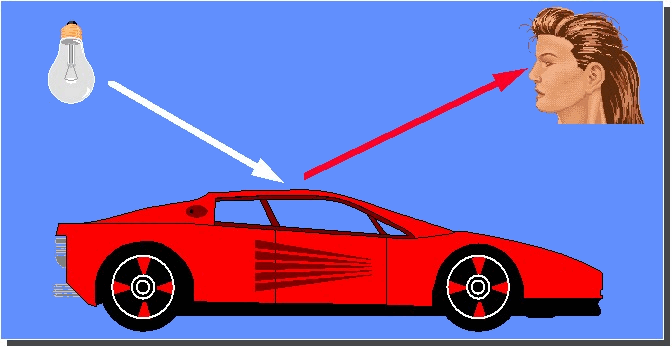

The normal situation of

viewing an object is illustrated in Figure 23. A “white”

light source is used to illuminate the object.

The colorants within the surface of the object

interact with the incident light and a proportion of the light is

reflected by the surface towards the eyes of the observer.

The observer perceives the colour of the surface.

|

Figure 23: Creation of colour by

the interaction of light with an object and an observer

|

Light absorption and reflection

When

white light is shone onto a white piece of paper, the surface reflects

some of the light towards the eye. The cone sensors in the

eye produce a balanced set of three visual signals, from the long,

medium and the short wavelength sensitive cones. The signal

is transmitted to the brain of the observer where the brain interprets

the balanced signal as “white”.

|

When

white light is shone onto a print layer or a coating layer the pigments

or dyes that are present absorb energy at some of the wavelengths in

the incident light. The light at the remaining wavelengths is

reflected back by the substrate or by any highly scattering “white”

pigments that may be present. The process is illustrated in

Figure 24.

|

Figure 24: Absorption and

scattering of light by a printed surface

|

The

light reflected from the surface will enter the eye however, however

some of the wavelengths are weakened or missing compared to "white"

light, as a result the set of signals sent to the brain is no longer in

balance. The brain interprets the unbalanced signal as a

coloured surface.

|

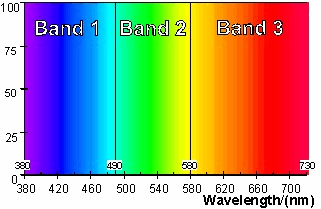

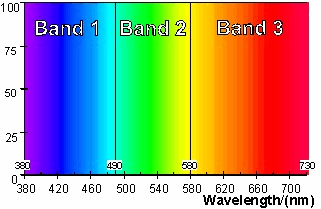

Conventional

pigments create colour by absorbing light within a band of wavelengths

within the visible spectrum. The creation of various colours

can be understood by considering the absorption and reflection of light

within, a blue band (band 1), a green band (band 2) and a red band

(band 3). The three bands of wavelengths shown in Figure 25

|

Figure 25: Blue, green and red

wavelength bands>

|

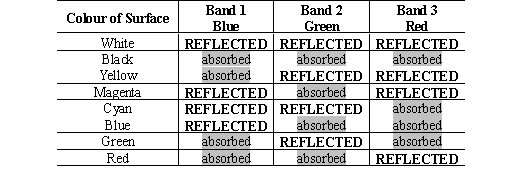

To

appear coloured, a material should mainly absorb light from wavelengths

within one, or at most two of the bands shown in Figure 25.

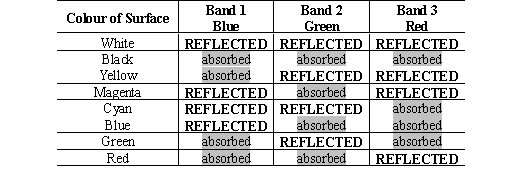

Table 2 illustrates the way in which the colour is created by selective

absorption within the three wavelength bands. If the material

absorbs in none of the bands then it will appear white. If it

absorbs equally at wavelengths spread evenly through all three of the

bands then it will appear grey or black.

Table 2: Surface colours and light

absorbed

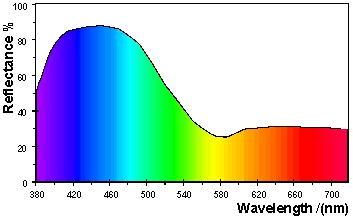

Reflectance spectra

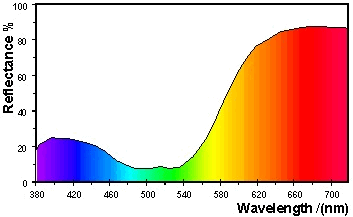

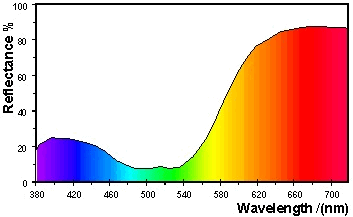

Red

surface

|

A

red object appears red because the material absorbs most of the light

with wavelengths in the blue band (1) and in the green band (2), only

the wavelengths in the red band (3) are reflected into the

eye. This is illustrated in Figure 26 for a red surface with

the CIE specification

L*

= 60.0, a* = 50.0, b* = 15.0.

|

Figure 26: Reflectance

spectrum of a red surface

|

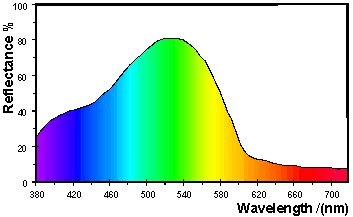

Green surface

|

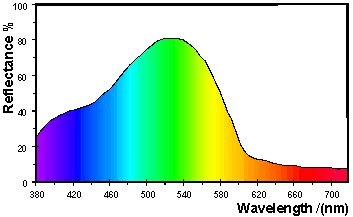

A

green object appears green because the material absorbs the light with

wavelengths in the blue band (1) and in the red band (3).

Only the wavelengths in the green band (2) are reflected into the

eye. This is illustrated Figure 27 for a green surface with

the CIE specification

L* = 70.0, a* = -50.0,

b* = 10.0.

|

Figure 27: Reflectance spectrum

of a green surface

|

Blue

surface

|

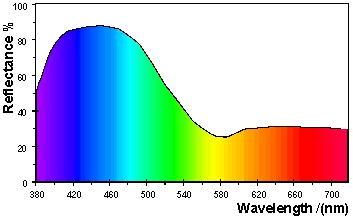

A

blue object appears blue because the light with wavelengths in the

green band (2) and red band (3) are mostly absorbed by the material and

only the wavelengths in the blue band (2) are reflected into the

eye. This is illustrated in Figure 28 for a blue surface with

the CIE specification

L* = 70.0, a* = -10.0,

b* = -35.0.

|

Figure 28: Reflectance spectrum

for a blue surface

|

|

H21: Light, Materials and Colour

|

©

James H Nobbs

[Colour4Free]

|